EPDM profiles – Reliable Coating and Flock Coating – Ideal for water-based painting systems

EPDM door seals perform two important functions: they act as weatherstrips and reduce the noise level perceived in the vehicle interior. Automobile door seals require specialty surface finishes to make sure that dirt particles will not adhere to them. However, getting a functional coating (anti-friction or flock coating) to adhere during the extrusion process is no easy task.

In the past, EPDM profiles had to be roughened continuously by means of rotating wire brushes – a complicated process with unpredictable results. Today, Plasmatreat's EPDM plasma systems are market leaders.

Topics on this Page:

Plasma pretreatment enables the use of VOC-free and solvent-free adhesives and anti-friction coatings.

The main effect achieved by Openair-Plasma® pretreatment is activation of material surfaces. On the otherwise non-polar EPDM profile surfaces, it produces specific chemical functionalities (such as OH groups, COC, CH3, hydroxyl, carbonyl and carboxyl groups). In addition, it increases the surface tension to > 72 mN/m.

This optimal preparation through plasma pretreatment makes it possible for the first time to use water-based adhesives and anti-friction coating systems that contain no VOCs (volatile organic compounds) to process EPDM profiles. Openair-Plasma® can be integrated easily into the process where it assures outstanding adhesion results.

Interesting success stories and press articles in this field

Openair-Plasma® pretreatment: high adhesion values and long-term surface tension without toxic chemicals

In numerous customer studies, the effects of different physical pretreatment methods such as corona and plasma pretreatment as well as chemical fluorizing were investigated in depth and compared with one another. Critical assessment criteria were the level of activation achieved on the profiles, the adhesion values, and the durability of the pretreatment.

The results speak clearly in favor of plasma pretreatment

The Openair-Plasma® process proved to offer excellent long-term stability, similar to that of fluorizing. EPDM profiles pretreated using the corona method showed a significant drop in surface tension only a short while after treatment.

Compared with fluorizing, pretreatment with Openair-Plasma® as a purely physical process delivers major processing and cost advantages. Moreover, the plasma technique is very much kinder to the environment as it requires no chemicals whatsoever.

Openair-Plasma® facilitates adhesion of solvent-free coating systems on thermoplastic elastomer (TPE) profiles

Modern profiles made of thermoplastic elastomers consist of a blend of EPDM and polypropylene (PP) and are extruded thermoplastically. The resulting products have only a very low surface tension and need to be pretreated before applying anti-friction coatings.

One major challenge to the automotive industry is achieving emission-free vehicle interiors by using VOC-free manufacturing processes. As an alternative to solvent-based coatings, it is possible to use water-based anti-friction coatings and dry lubricants. However, these will not adhere to the substrate unless it has an especially high surface tension.

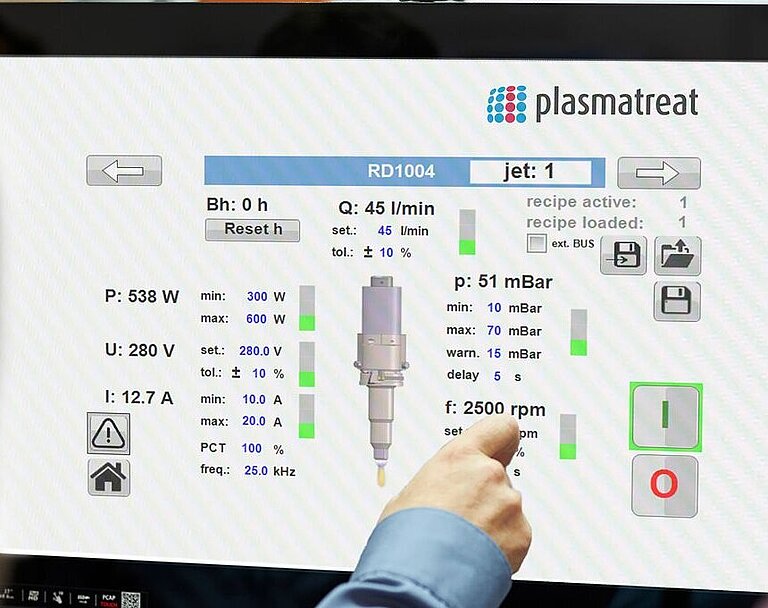

At the same time, profiles made of TPE have thermally sensitive surfaces and can easily be damaged if the pretreatment is too intense. With all these conflicting requirements, it is difficult to achieve reliable activation over the whole range of products. Nevertheless, this can be done by using patented Plasmatreat rotary jets RD 1004. These can treat a wider area, distributing the plasma power uniformly over the treatment zone.