Plasmatreat SAS

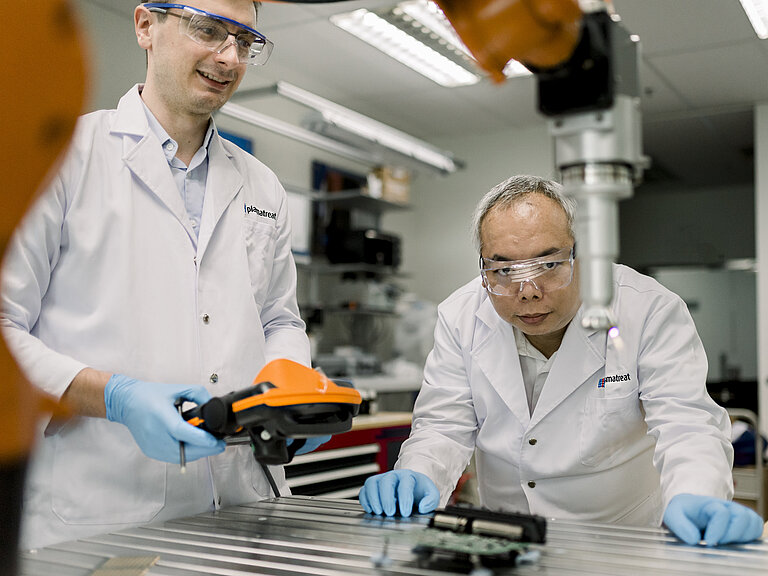

With more than twenty years of experience in all industrial applications and more than 300 machines in France,

we offer our customers a wide range of high quality technical and sales support:

From application development support, laboratory testing and contract service to rental systems, French customers receive the best possible support.

In addition, our service department provides fast and easy spare parts and is ready to help - remotely or on-site.

Optimal support for the French market

We have been managing, directing and controlling all Plasmatreat sales and service activities in this region since 2000. Through direct customer consultation, we enable our customers to successfully integrate and operate our innovative Openair-Plasma® treatment systems for industrial fine cleaning and surface activation, as well as our PlasmaPlus® coating technologies.

Our optimal location close to major research centers and at the center of important industrial investment decisions makes us easily accessible to our existing and potential customers and provides the best and fastest service.

We organize and participate in trade fairs, seminars and exhibitions and actively support our extensive network of service technicians and distributors throughout the region to serve our customers as efficiently and effectively as possible.

Comprehensive plasma know-how for the French market

The french subsidiary of the world market leader for atmospheric plasma systems from Steinhagen/Germany offers users standardized and individualized solutions for a wide range of applications with a broad spectrum of plasma systems and components. Plasmatreat's specially developed Openair-Plasma® technology can be used for ultra-fine cleaning, activation, and plasma-assisted deposition of surfaces. In plasma activation, oxygen- and nitrogen-containing groups are grafted onto the surfaces of polymer substrates, thereby increasing their surface energy using simple compressed air. With the aid of the special PlasmaPlus® technology, nano-coatings are applied to the substrates, creating specific surface functionalities, thus improving processes even further.